3D print

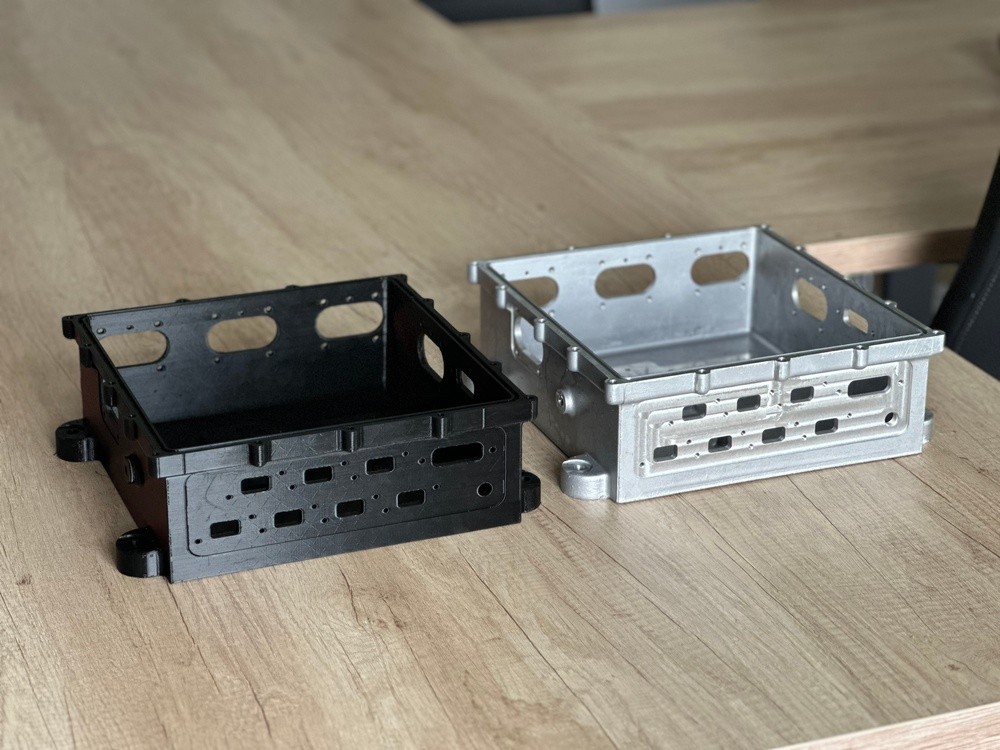

Creating a functional prototype is an essential step in the process of introducing products to mass production using metal casting techniques. A correctly made model allows for the assessment of the validity of the applied design solutions, the implementation of necessary corrections, and the elimination of errors. It facilitates the verification of the usability features of the final product and ensures compliance with customer expectations.

3D Printing Service Traditional methods of prototype creation in foundry, such as trial castings, sheet metal forming, or CNC milling, are unfortunately quite time-consuming and costly. However, there is a more economical and faster alternative in the form of a 3D printing service using dedicated thermoplastic materials. The three-dimensional prints produced in this way are characterized by high mechanical strength, as well as excellent reproduction of the geometry and all details of the prototyped element.

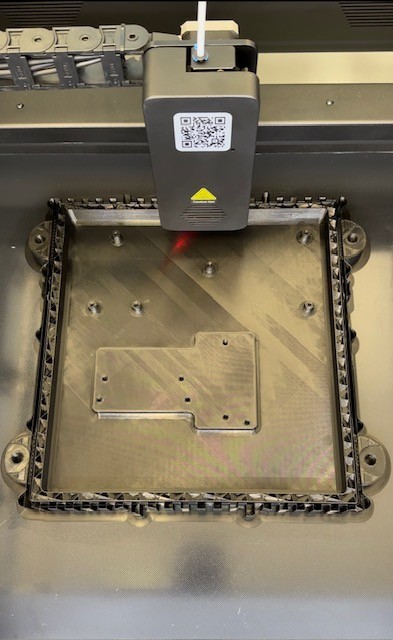

RAPID PROTOTYPING – 3D PRINTING SERVICE At Odlewnia Kowala, we use FDM (Fused Deposition Modeling) 3D printing technology. This 3D printing service is dedicated to the rapid prototyping of elements made of metals and non-ferrous alloys such as copper, aluminum, brass, or bronze. The FDM method is currently considered the most versatile and practical technique – steadily gaining popularity. It is ideal for creating functional prototypes of machine and vehicle parts, unique tools or equipment, and artistic products.

Modern FDM 3D printing allows the production of even very complex casting prototypes in a short time. It is also several times cheaper than the prototyping of metal models used in large-scale production – which requires labor-intensive mechanical processing methods. Our FDM 3D printing service allows the preparation of prototypes in various forms – as split models, non-split models, and models with removable parts. They are not inferior in quality to prototypes made using "analog" techniques.

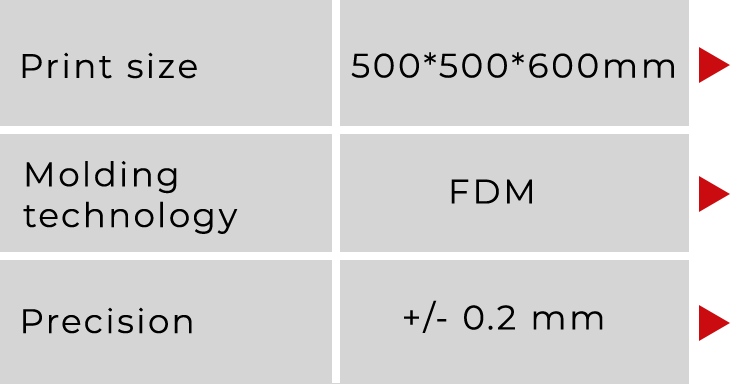

The professional 3D printers used at Odlewnia Kowala, branded Creality, feature a working area of 500500600 mm and precision in applying individual layers at the level of +/- 0.2 mm. We use thermoplastic materials from the polyester family (ASA, PLA, PETG, PCTG), nylon, polyurethane, or ABS as filaments.

FDM 3D PRINTING SERVICE – HOW DOES IT WORK?

The procedure for creating a casting prototype using FDM 3D printing can be divided into three basic stages:

-

Modeling — The three-dimensional models of the prototyped element are developed using specialized CAD software or a 3D scanner. Three-dimensional printing requires consideration of numerous parameters such as resolution, shape, and degree of infill, wall thickness, number of outlines, and top and bottom layers. The entire preparation process for printing is quite complex and requires significant experience, but for our specialists, it's everyday work.

-

Printing — Involves gradually, layer by layer, depositing the thermoplastic material (filament) through the working head of the 3D printer, moving according to the programmed algorithm. The print head is equipped with a function for heating the applied material to the appropriate temperature and an extruder, which delivers the filament at a speed appropriate for the task.

-

Finishing — The surface of the printed element is usually rough and porous, so it needs to be smoothed – mechanically or chemically, depending on the filament used. At this stage, material excesses and any supports (if necessary) are also removed.

3D PRINTING SERVICE – WHY IS IT WORTH IT?

Prototyping using 3D printing technology is an excellent choice for non-ferrous metal casting. Elements made of thermoplastic materials accurately replicate the characteristics of the final product, exhibiting high mechanical, chemical, and thermal strength. However, their production is many times faster and cheaper compared to prototypes created using traditional methods such as casting, sheet forming, or CNC machining. It is also easier to introduce necessary corrections and modifications if client expectations change.

3D printing technology allows easy and efficient testing of product functionality at an early stage of development before moving on to costly mass production stages. Three-dimensional, physical models make it significantly easier for designers to share their ideas with colleagues and clients than two-dimensional images on a computer screen. In a single 3D printing session, we can quickly create functional, working prototypes and conceptual models consisting of several or even dozens of interacting elements.

With our 3D printer, we can offer our clients professional printing of prototype castings.

Basic Parameters

Basic Parameters

Materials for 3D printing

Materials for 3D printing

![]() PLA

PLA ![]() ASA

ASA ![]() Nylon

Nylon

![]() PETG

PETG ![]() ABS

ABS

![]() PCTG

PCTG ![]() Poliuretan

Poliuretan