Die Castings

In our company we manufacture pressure castings:

from aluminium alloys

from aluminium alloys

of unit weight up to 4 kg

of unit weight up to 4 kg

in medium and large batches

in medium and large batches

with different degrees of finish

with different degrees of finish

with delivery to the customer

with delivery to the customer

at competitive prices

at competitive prices

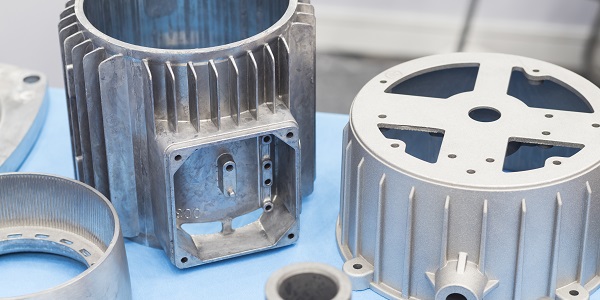

Depending on the customer’s requirements, additionally we can offer:

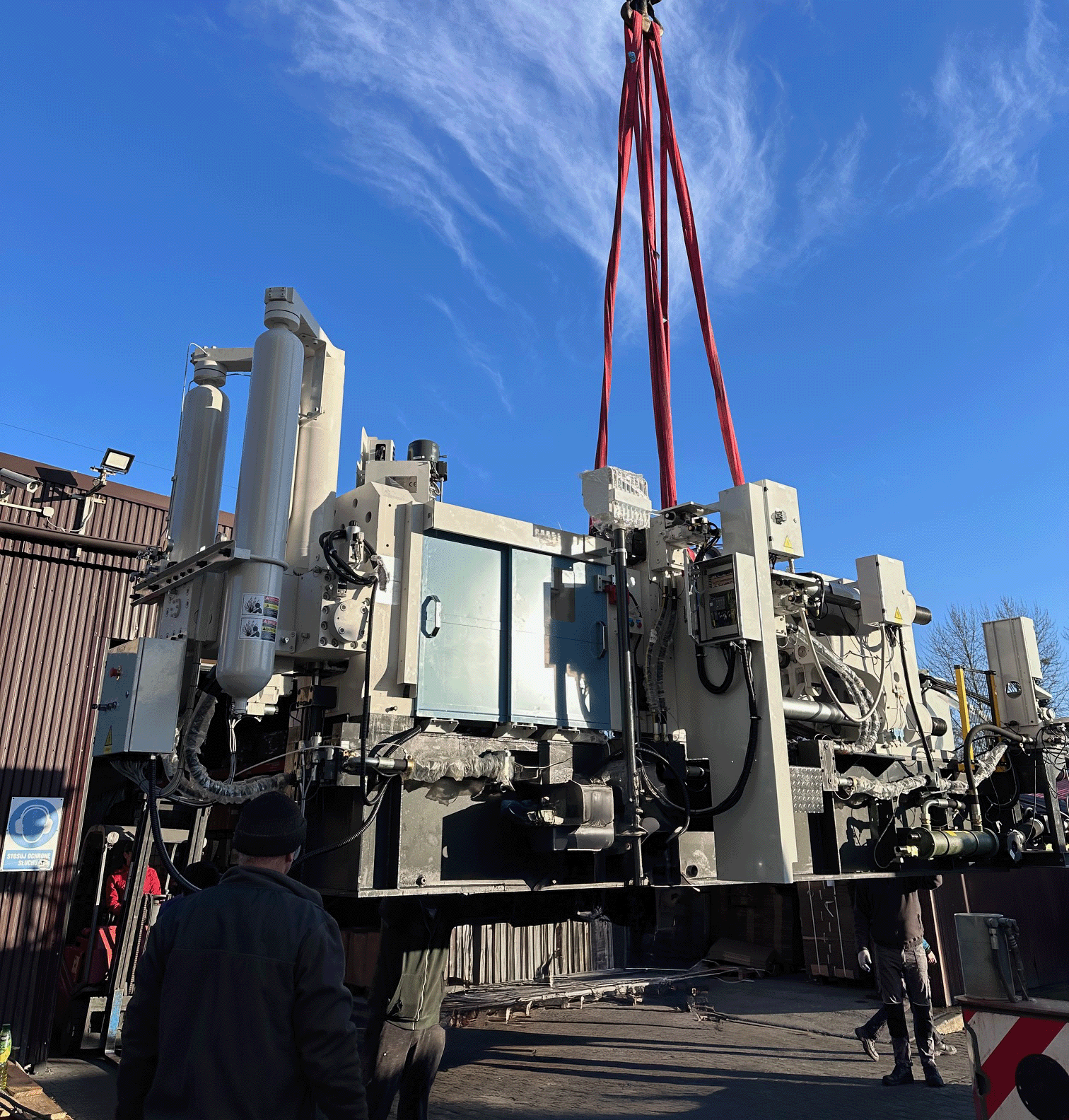

Breakthrough for the Company – New Fully Automated IDRA Machine

We proudly present our new fully automated casting machine from IDRA, a renowned Italian manufacturer that has been setting the standards in casting technology for years. This innovative machine combines top precision, repeatability, and efficiency, allowing us to offer the highest-quality aluminum castings.

Key features of the machine:

✅ Full automation – minimizes operator involvement, increasing safety and process efficiency.

✅ High precision – advanced control ensures perfect detail reproduction.

✅ Energy efficiency – optimized technology reduces energy and raw material consumption.

✅ Speed and repeatability – automatic pouring system and parameter control guarantee uniform, defect-free castings.

✅ Modern control system – intuitive interface enables easy configuration and process monitoring.

✅ Versatile applications – capable of casting a wide range of aluminum components for various industries.

Machine in the process of unloading.

The company owners at IDRA's headquarters in Italy with the new machine in

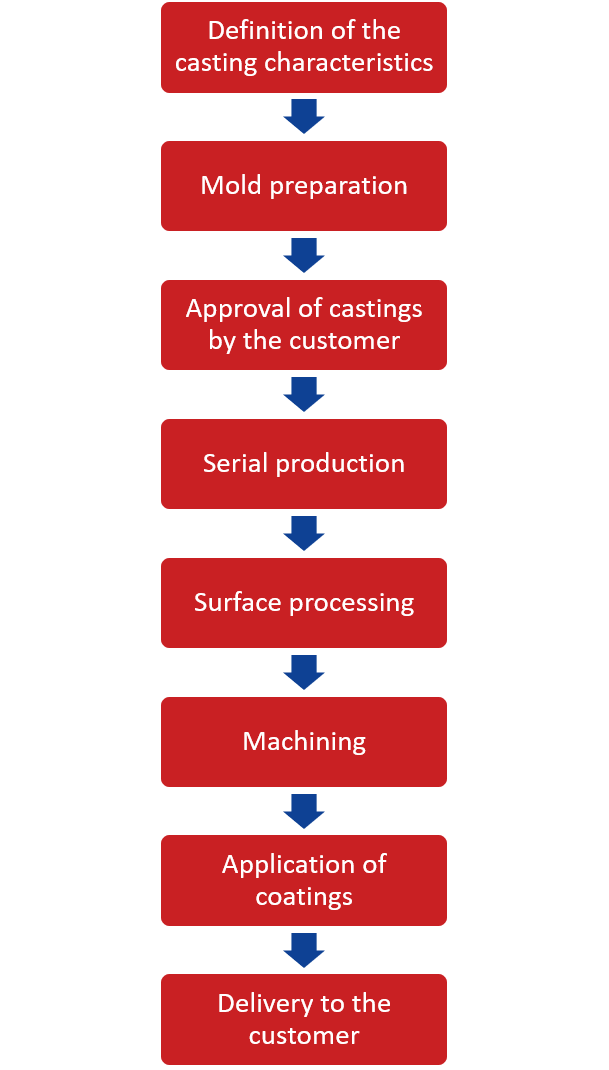

Production process

We implement casting production on the basis of the customer’s technical documentation or on the basis of a provided model that we 3D scan. Having specified all the features of a given detail with the customer, we forward their documentation to one of several experienced tool shops we cooperate with. Together we develop a design of a mould in order to obtain its optimal structure. Next, the tool shop produces the tool according to a set schedule, which we monitor on a regular basis. When the mould is ready and the test batch has been produced, we send the castings to the customer for approval or we 3D scan them so as to verify their dimensions. After approval we launch the serial production. It is a very efficient process, supervised by a group of our experienced operatives, who work on the machines, supervise subsequent production stages, and inspect products in order to detect defects, if any.

50 employees at the pressure foundry department

Area of the pressure foundry hall: 1000 m2

Number of pressure machines: 7

Clamping force 100 to 560T

Send your inquiry to the address: marketing@odlewnia-kowala.com.pl